So, after reading everyones

horn problems I decided to try and

fix mine. One of the two worked but it sounded like I was squeezing the life out of a duck. Anyway, after I read that some people had some successes fixing there own horns I figured it should be fairly easy to do it while they are on the boat. Well its not... and after an hour of frustration, I removed them from the boat so I could work on them at home. If I knew then what I know now, I would have left them on, because now I have to somehow reconnect the wiring.

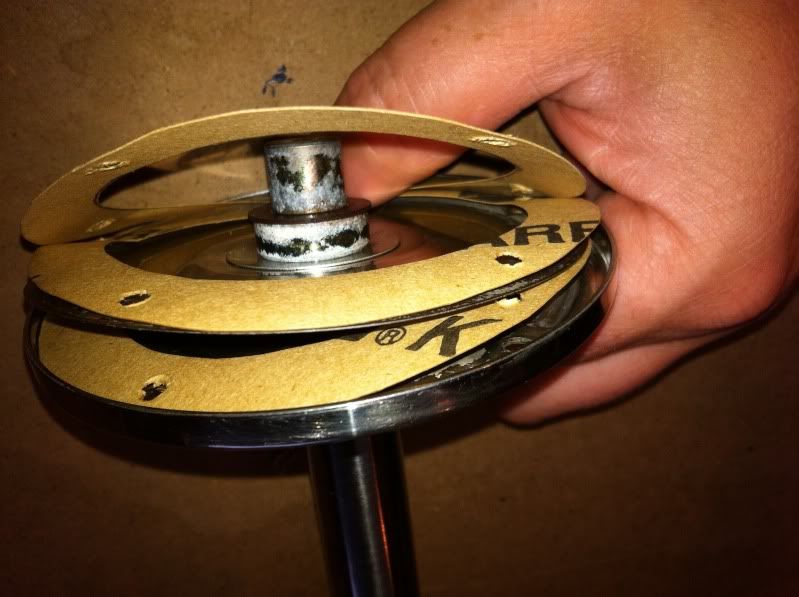

When I opened them up there was quite alot of corrosion on the outer ring of the main mechanism. It butts up to two paper (gasket?) rings, the diaphram, another paper ring and then the

horn body. I found that the paper rings had deteriorated and must have held moisture against the main mechanism, enough so, that it caused the ring of corrosion.

Heres a pic of all the original parts. Rear casing, diaphram, main machanism (for lack of a better term), Paper rings and the

horn body. Note the corrosion and the condition of the paper rings

After the disassembly, I cleaned up any rust with a wire brush.

What I found was that the breakdown of the paper rings are why the horns failed. Luckily, I had a roll of gasket making material laying around and I cut out 6 new paper rings using the main mechanism as a template.

Next I reassembled like pictured here.2 paper rings, the diaphram, 1 paper ring and the

horn body.

Then I attached the main mechanisim using the 5 screws but I only turned them on about five turns before I tested the

horn with a 12v source.