When I graduated from college in 1985, it happened that a fraternity brother of mine (who, BTW, was Mr. Kansas that same year) had recently become very religious and decided to divest himself of virtually all his earthly belongings. Among them was a kick-butt Sansui 160W receiver and (among other things) a pair of Bose 901 Series IV speakers with equalizer. He had bought this system in Guam while in the Marines between high school and college. It was a system that produced sound like I'd never heard in my life and at a volume I'd never heard in my life

. On Friday afternoons this system provided the musical entertainment for pretty much the entire campus from the front windows of our house

. The receiver was built in 1980 and weighs around 50 lbs, all solid state but with seriously heavy duty discrete components, separate amp driver boards for each channel, 8 high-output final transistors mated to HUGE heat sinks, etc. To get modern "BPC" (black plastic crap) components that can hold a candle to this, you have to spend BIG money.

So, he really wanted to get rid of it all and you know, you have to help out a brother. So I bought the whole thing. Now I realize you audio types started rolling your eyes as soon as you saw the word "Bose." They've made a lot of over-marketed, over-hyped stuff and a lot of it is just crap. However - the 901's, for anyone who isn't too much of a snob to admit it, is among the best speaker systems ever built for the home market,

when they are properly positioned, equalized, and driven. I love the power limitation statement on the 901 specifications: "Unlimited, in non-commercial applications."

Fast forward to about a year ago. After several years of "fraternity use" and over 20 more years of family use and just plain age, the foam surrounds on all 18 of the speaker drivers had rotted and failed. You can see it if you look around the perimeter of the blue cones, after removing the covers:

I bought a set of new foam surrounds, removed all 18 drivers, and set myself to the task of carefully scraping and removing the remnants of the original foam & glue, then installing the new foam and realigning each cone one at a time. I expected this to be a monumental task going in, and I grossly underestimated it.

Along the way I pulled out all the corroding connection hardware and replaced it all with new stainless.

Before reinstalling the drivers back into their cabinets, I soldered leads onto them in order to make the job a little easier. I used heat sinks on the connectors so that I wouldn't damage the composite driver frames.

While this was going on, I took the opportunity to lightly sand the walnut veneer cabinets, and apply 2 coats of Watco natural oil (basically boiled linseed oil).

And, I took the time to disassemble and check the equalizer, and it's a good thing, it was in BAD shape. Of the 10 electrolytic capacitors on the board, one of them had leaked and a couple of others were getting pretty far out of spec.

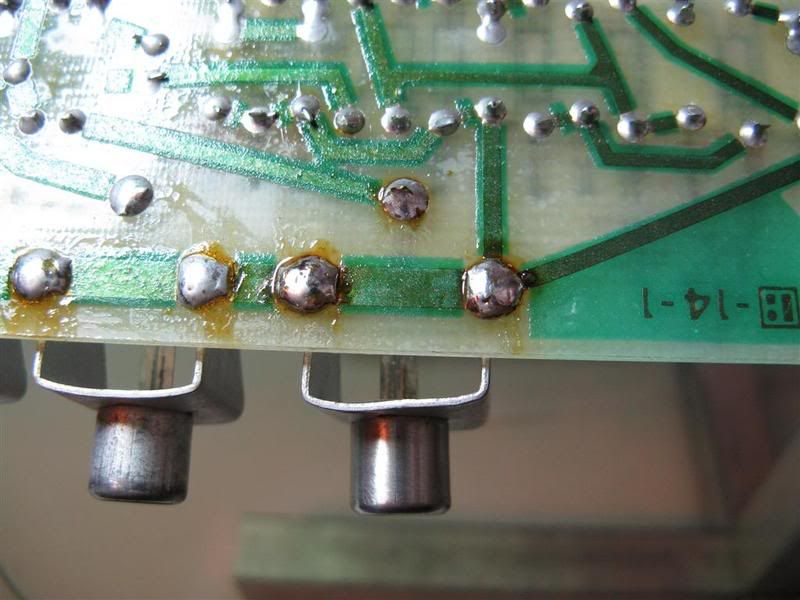

Worse yet, one of the audio connector joints on the board had broken somewhere along the way.

I removed that connector entirely, cleaned up all three contacts, and reinstalled. I did all the solder work with a Hakko 936ESD temperature controlled station, and Multicore 63/37 RA solder, .022" diameter.

Here it is with all new Nichicon caps, repaired connector, all connectors polished, Do-Oxit applied to both sliders, and a new cord:

And, the finished EQ with a couple coats of Watco on the walnut cabinet, ready for another 30 years of enjoyment: